Pagina 1 di 1

Motori sincroni a 60Hz

Inviato: 25 dic 2011, 23:12

da nullo

In caso di un gira con motore a 110 V 60Hz quale strada consigliate per avere la giusta velocità di rotazione?

Convertitore elettronico di frequenza, oppure intervento meccanico?

Re: Motori sincroni a 60Hz

Inviato: 26 dic 2011, 20:58

da baldo95

Convertitore elettronico di frequenza con possibilità di tensione stabilizzata, eviti i vari sbalzi di tensione ed ovviamente hai più precisione che per il gira gira è essenziale

Re: Motori sincroni a 60Hz

Inviato: 26 dic 2011, 23:22

da marziom

i motori sincroni hanno già una velocità di rotazione abbastanza precisa, se fai un accoppiamento con i corretti rapporti la velocità di rotazione sarà precisa (almeno quanto è precisa la nostra frequenza di rete).

Il problema semmai è che il tuo è a 60Hz...comunque volendo andare oltre, sicuramente la strada elettronica è da preferire.

Re: Motori sincroni a 60Hz

Inviato: 27 dic 2011, 13:17

da nullo

Curioso (e furbo?):

http://www.altmann.haan.de/turntable/

Motor Control ...

How do we accomplish a steady motor speed and a smooth rotation? Of course we do not control the stepper motor with digital steps, as this would lead to a rather rough ride. We treat the stepper as if it was a synchronous motor (which it is), so we feed it with sinewaves. A bipolar stepper motor has two coils (just like a AC synchronous motor).

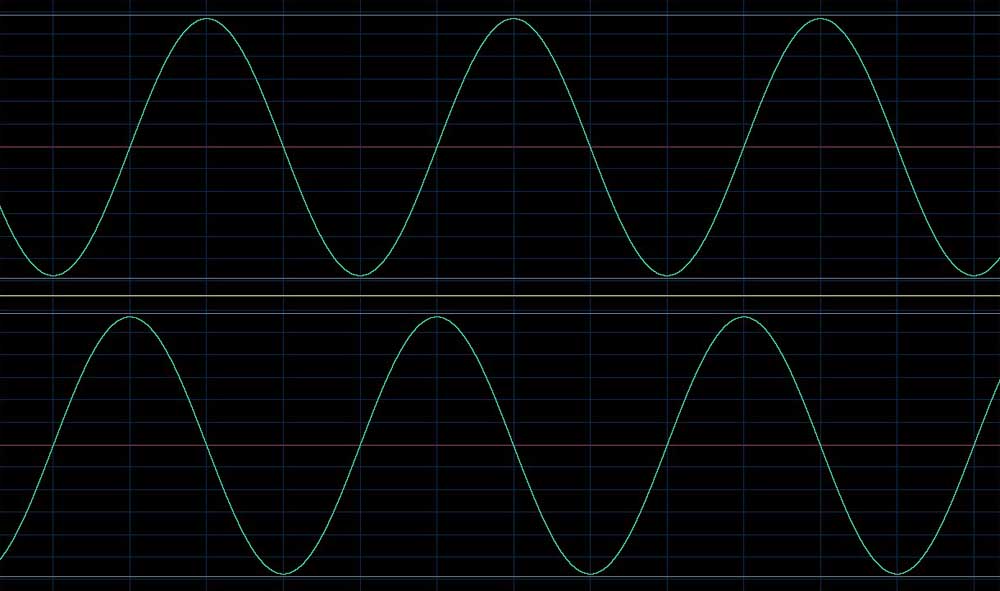

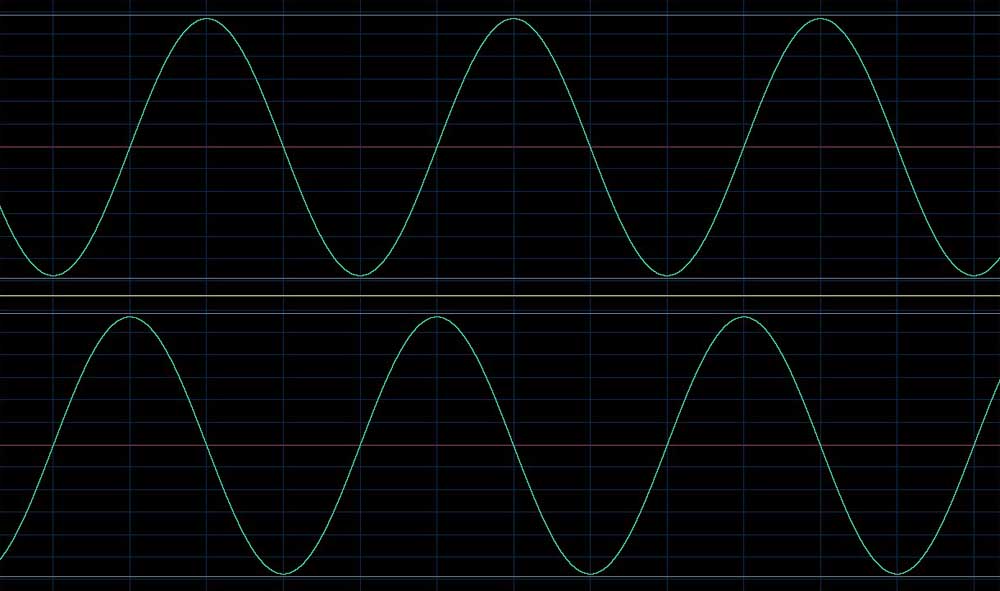

We need a sine-wave for coil #1 and a 90 deg offset sine wave for coil #2 (as I said, just like AC-synchronous).

This is often done with a mains transformer plus a capacitor for delaying the sine for coil #2. This is not really accurate and also not adjustable.

We want something better. So what do we do ?

We just generate a 50 Hz (or 60Hz) sine wave on the computer using a music program (like cool edit), plus a second sine wave with 90 deg. delay.

Looks like this (top channel leads 90 deg. compared to bottom channel) :

Connect the sound output of your computer to a spare stereo-amplifier, in order to play this sine-wave pattern. Connect both coils of the stepper motor to the amplifier's speaker posts, just as you would connect a pair of speakers. Slowly turn up volume... and ... the motor rotates with a steady 250 rpm (300 rpm if you feed 60Hz). With the volume control you can adjust the sine-wave-voltage for least motor-vibration. This is the basic setup for testing and operating a motor.

Since this is a DIY project you never know the exact diameter of the platter and the motor pulley before. You just know after you hold the parts in your hand. No problem. With this setup you can strobe the platter to do exactly 33 1/3 rpm, because you can change the frequency that you feed into your motor. You may end up feeding the motor with 53.6 Hz for an accurate platter speed. Once you have determined the correct frequency, you may burn that signal on a CD and use your CD-player to control the turntable motor with crystal precision (if you play records your CD-player has no work anyway).

Another way of controlling your turntable motor: The Altmann TERA-PLAYER is able to provide 2 independend precision sine waves, which are read from SDHC card.

The world of high-fidelity turntable-sound is yours.

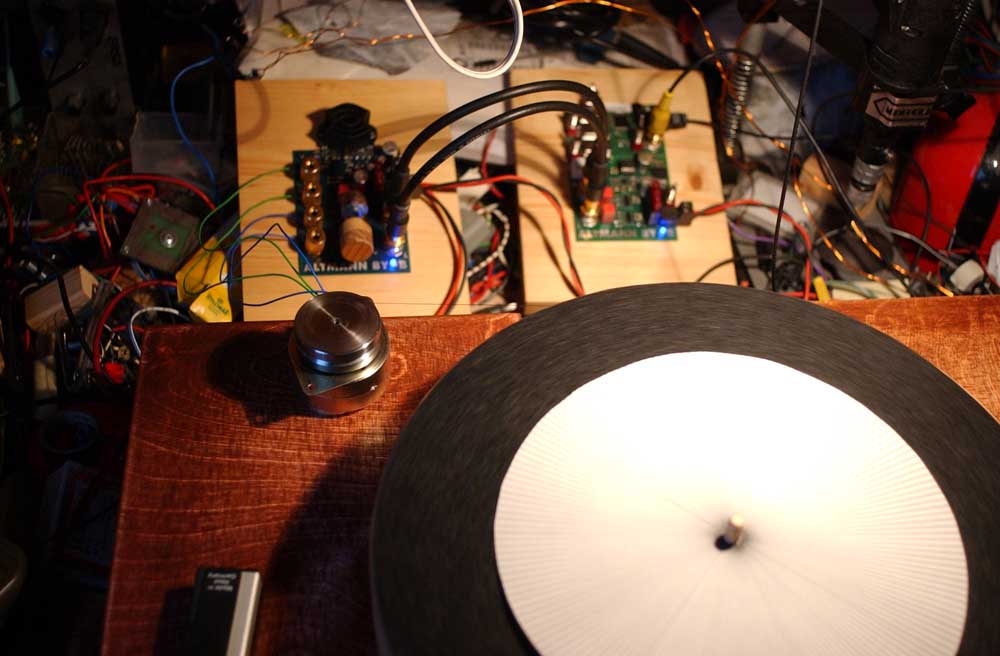

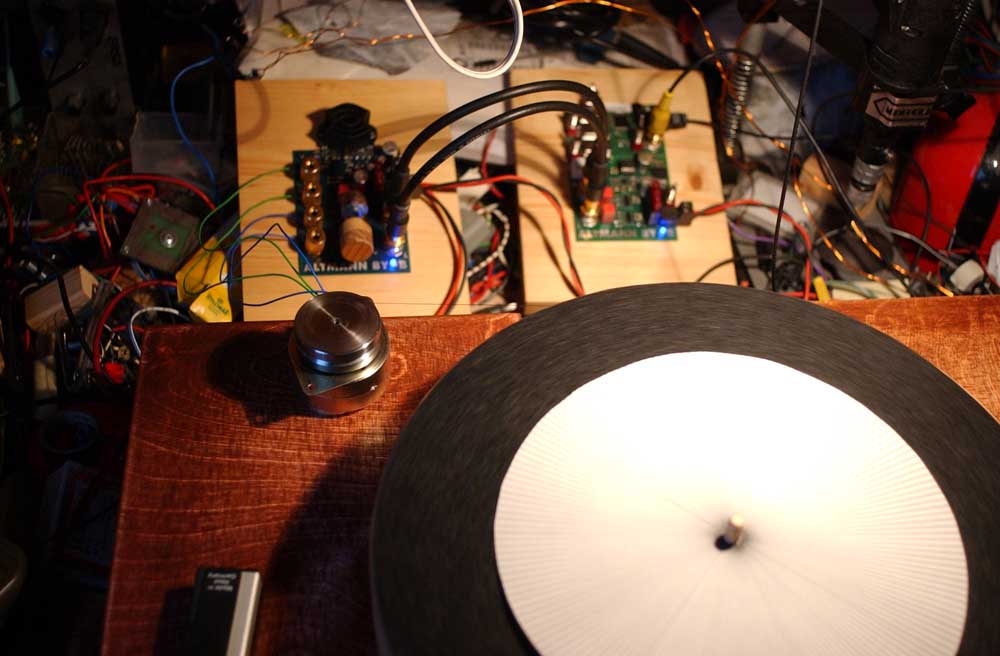

See below: 7.5 stepper powered by Attraction DAC and BYOB amplifier. Notice the strobe mat.